Big-picture folks are running the numbers on power, cooling, and computation, envisioning the datacenter of the future. Meanwhile your network, miles and miles of cable, keeps it all tied together and connected to the real world. Reality is a big factor, and keeps you maintaining cable runs long after they’re installed. Network cabling is a part of the infrastructure that only becomes visible when it fails — or when you bring it down for testing and tracing.

Big-picture folks are running the numbers on power, cooling, and computation, envisioning the datacenter of the future. Meanwhile your network, miles and miles of cable, keeps it all tied together and connected to the real world. Reality is a big factor, and keeps you maintaining cable runs long after they’re installed. Network cabling is a part of the infrastructure that only becomes visible when it fails — or when you bring it down for testing and tracing.

Acceptable Casualties?

Even a short interruption in network connectivity can light up the help desk phones like fireworks, and get issues escalating before people realize it was just a quick test. Scheduled downtime for testing often costs weekend overtime and inconvenience, and in today’s 24/7 datacenter even that may not be acceptable. QoS hits, expensive dead air from broadcast servers, interrupted real-time data links, broken promises to customers — the list of consequences goes on.

Interrupting live networks is painful. But sometimes you’ve got to do work in the cable closets, server rooms, and other crowded and complex rivers of wire that are your responsibility. Does there have to be an acceptable amount of downtime for tracing and testing wires? There are a few low-impact methods for locating cable ends which are popular but disruptive. There is one newer strategy, though, which can lead you right to the cable end you seek without network disruption or disconnection.

Tones and Testers

Tones and Testers

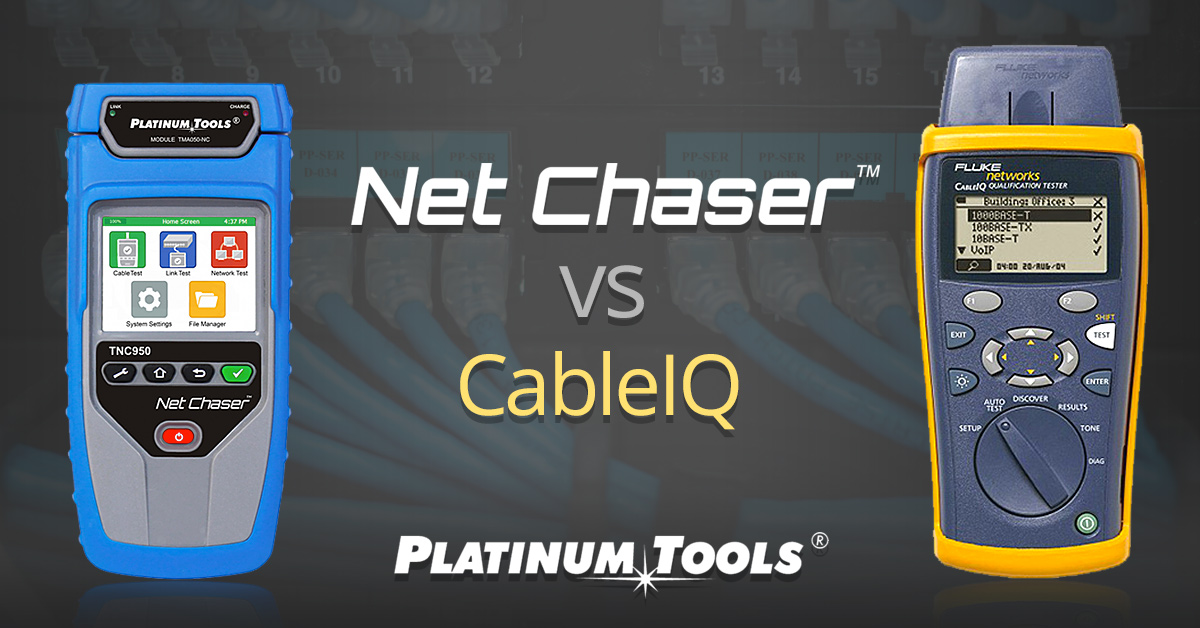

Hailing from the days of craft technicians testing voice circuits for dial tone with their butt set, tone testing is a straightforward way of locating the other end of a cable, especially in a remote location. The tone goes in one end of an offline circuit, and the technician checks all the other ends in the server room or data closet until he or she finds it. It’s even possible to be checking the wrong location if the cable runs branch out to various locations. Only problem with this method is it will not work on a live network. Testers such as Platinum Tools’ Cable Prowler, Net Prowler, and Net Chaser can provide the tones for testing.

Remotes Tag Multiple Cables

Using remotes with a cable tester can help locate one or more cables at the far end, but doing so still requires disconnection from the server, switch, or router and downtime for testing. The three cable testers mentioned can test cabling using remotes. You can also run a series of cable verifications while you’re at it, especially if you’re testing unused cable installed as backup. But what about that case where some cables wind up in closet A, others in closet B? Plus, this method is it will not work on a live network.

Link Light — Testing without Disruption, At Last

A great feature on the Platinum Tools Cable and Network Testers allows live testing when you just can’t afford to go offline even for a quick toning or using remotes to tag cables. Link Light is a clever trick where the tester, connected to an active network cable or port, makes the port light for that circuit flash at a regular rate. You can vary the flashing rate so that it’s easy to distinguish from other network activity, making it simple to identify your cable even if you have to check several locations — just open the closet door, look for the unique flashing light, and tag your connection.